| Number of full bridges | 2 |

| Vs (Min) (V) | 8.2 |

| Vs ABS (Max) (V) | 47 |

| Full-scale current (A) | 1.6 |

| Peak output current (A) | 1.8 |

| RDS(ON) (HS + LS) (mOhms) | 1280 |

| Sleep current (uA) | 10 |

| Control mode | PH/EN |

| Control interface | Hardware (GPIO) |

| Micro-stepping levels | 4 |

| Features | Current Regulation |

| Rating | Catalog |

| Operating temperature range (C) | -40 to 85 |

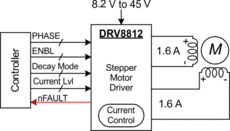

- 8.2-V to 45-V Operating Supply Voltage Range

- 1.6-A Maximum Drive Current at 24 V and

TA = 25°C - Dual H-Bridge Current Control Motor Driver

- Drive a Bipolar Stepper or Two DC Motors

- Four Level Winding Current Control

- Multiple Decay Modes

- Mixed Decay

- Slow Decay

- Fast Decay

- Industry Standard Parallel Digital Control Interface

- Low Current Sleep Mode

- Built In 3.3-V Reference Output Small Package

and Footprint - Protection Features

- Overcurrent Protection (OCP)

- Thermal Shutdown (TSD)

- VM Undervoltage Lockout (UVLO)

- Fault Condition Indication Pin (nFAULT)

- APPLICATIONS

- Automatic Teller Machines

- Money Handling Machines

- Video Security Cameras

- Printers

- Scanners

- Office Automation Machines

- Gaming Machines

- Factory Automation

- Robotics

All other trademarks are the property of their respective owners

The DRV8812 provides an integrated motor driver solution for printers, scanners, and other automated equipment applications. The device has two H-bridge drivers, and can drive a bipolar stepper motor or two DC motors. The output driver block for each consists of N-channel power MOSFET’s configured as full H-bridges to drive the motor windings. The DRV8812 is capable of driving up to 1.6-A of output current (with proper heatsinking, at 24 V and 25°C).

A simple parallel digital control interface is compatible with industry-standard devices. Decay mode is programmable.

Internal shutdown functions are provided for over current protection, short circuit protection, under voltage lockout and overtemperature.

The DRV8812 is available in a 28-pin HTSSOP package with PowerPAD? and in a 28-pin QFN package PowerPAD? (Eco-friendly: RoHS & no Sb/Br).